Those involved in construction and renovation are certainly familiar with scaffolding. Currently, there are two main types on the market: modular scaffolding systems and traditional steel pipe and coupler scaffolding. Don’t let the names convoluted fool you; the core difference is actually quite simple, like comparing “ready-made fast food” to “grocery shopping and cooking yourself”—one is easier, the other is more time-consuming. Today, we’ll explain it in plain language, so even beginners can easily distinguish between them.What to do when scaffolding work encounters severe weather?

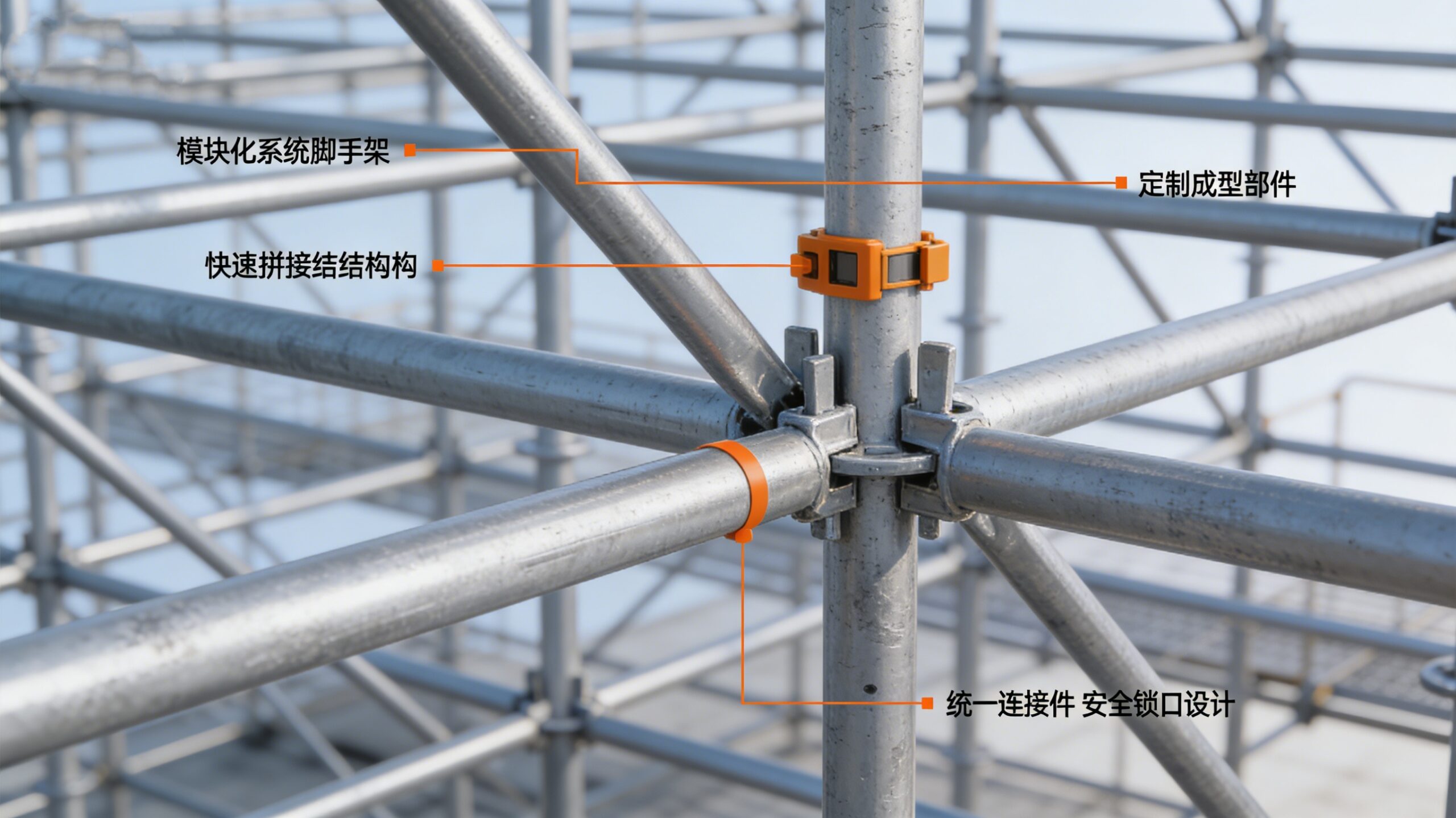

First, let’s talk about installation speed. It’s like a tortoise and the hare race. Traditional scaffolding consists entirely of individual steel pipes and couplers. When assembling it, you have to lay out the pipes first, then tighten the couplers to secure them, assembling them one by one, like building a complex Lego set. It’s time-consuming and labor-intensive; several people might spend a whole day just to assemble enough for a small area. Modular designs are different. They come pre-assembled frame modules, like building blocks. Just align them, snap them together, or insert them – no need to tighten each fastener individually. Two people can assemble a large section in half a day, doubling efficiency.Do Scaffolding installations in cold, snowy regions require additional safety measures?

The difference in safety is also significant. Traditional designs rely entirely on fasteners for fixation. If the fasteners aren’t tightened properly or loosen over time, the steel pipes can wobble, posing a safety hazard. Furthermore, the pipes vary in length, leading to gaps during assembly, making it unsettling to step on. Modular frames, on the other hand, are integrally molded with fixed connection points, making them extremely stable and wobbly. The surface is smooth, without any messy gaps, providing a solid and worry-free experience.Additional Reinforcement Measures for Scaffolding in Windy Areas

In terms of ease of use, one is “easy for beginners,” while the other requires an experienced technician. Traditional scaffolding requires skill; you need to know how to position the steel pipes and tighten the couplers securely. Beginners without experience are hesitant to even attempt it, fearing that a misaligned or poorly secured frame would render all their work useless and dangerous. Modular scaffolding, on the other hand, is much less demanding. The standardized modules allow both beginners and experienced scaffolders to assemble it at a glance, eliminating the need to memorize complex techniques and saving significant learning time.

Durability and maintenance also differ dramatically. Traditional steel pipes are prone to rust, especially after rain or snow, and couplers are easily damaged. After use, each pipe must be wiped clean and inspected individually, and broken ones must be replaced, making maintenance both expensive and time-consuming. Modular scaffolding, mostly made of galvanized or powder-coated materials, is resistant to wind and rain and less prone to rust. With fewer parts, it can be simply stacked after use, and inspection is straightforward—just a quick glance at the modules for damage, without needing to disassemble each coupler individually, making maintenance much easier.

Finally, in terms of flexibility, traditional scaffolding has a slight advantage. Traditional steel pipes can be easily cut and spliced, making them suitable for irregularly shaped sites and buildings, much like “molding clay”—you can shape them however you want. Modular scaffolding, on the other hand, has fixed-size modules. For particularly irregular sites, special accessories may be needed, reducing flexibility slightly, but it’s perfectly adequate for most engineering scenarios.

In short (or rather, let’s be blunt), there’s no inherently good or bad scaffolding; it all depends on your needs. If you’re pressed for time, want to avoid hassle, and prioritize safety, modular scaffolding is the way to go. If the site is special and you want to save on upfront costs, traditional scaffolding will suffice. However, in today’s construction industry, everyone prioritizes convenience and safety, making modular scaffolding increasingly popular. After all, nobody wants to be constantly dealing with a bunch of steel pipes and fasteners, right?

One more thing: regardless of the type used, it must be done according to regulations. Don’t just assemble it haphazardly. Safety isn’t something you can rush or cut corners for; if it’s not securely erected, you’ll regret it later. Especially when working at heights, only when the scaffolding is stable can the workers feel at ease.