In construction projects, used scaffolding is a popular choice for cost control due to its low price and high cost-effectiveness. However, the service life, damage level, and compliance of used scaffolding are uncertain. Blindly purchasing it can easily create safety hazards and even lead to construction accidents. Therefore, it is crucial to avoid core risks when purchasing used scaffolding and to strictly implement a full-process inspection. Below is a detailed breakdown of the main risks and key inspection points for purchasing used scaffolding, helping you avoid pitfalls and make safe purchases.How to Evaluate the Quality and Reputation of a Scaffolding Manufacturer

The first step in purchasing used scaffolding is to identify and mitigate the core risks in advance. First, there is the structural safety risk, which is the most critical hidden danger. Used scaffolding may have undergone long-term heavy-load use, resulting in problems such as member fatigue, weld cracks, and severe corrosion, significantly reducing its load-bearing capacity and making it prone to collapse during use. Second, there is the compliance risk. Some used scaffolding may be outdated models that do not meet current national or international safety standards (such as BS, ANSI, CE certification requirements), or lack production qualifications and test reports, making it unable to pass project safety acceptance. Thirdly, there is the risk of hidden damage. Some damage (such as internal cracks in members or wear on fasteners) is difficult to detect visually, but it can seriously affect the safety of use. Fourthly, there is the risk of after-sales guarantee. Second-hand transactions are often “one-off deals” lacking quality assurance services, making it impossible to hold anyone accountable for subsequent quality problems.How to Obtain Bulk Quotes for Scaffolding Systems in Large-Scale Projects

Key Inspection Point 1: Verify qualifications and documents to control compliance from the source. First, require the seller to provide the original production qualifications and factory inspection reports of the scaffolding to confirm that the product meets the safety standards of the project’s country, avoiding the purchase of outdated or non-standard products. Second, check the usage records to understand the service life of the scaffolding (the normal service life of high-quality scaffolding is about 5-8 years; use beyond this period requires caution) and past construction scenarios (if it has been used for a long time in high-altitude or heavy-load projects, the risk of damage is higher). If the seller cannot provide relevant documents, or the document information does not match the actual product, the purchase should be abandoned decisively. For imported second-hand scaffolding, customs declaration documents and compliance certification documents should also be checked to ensure compliance with local market access requirements.Chinese-made scaffolding exported to Europe

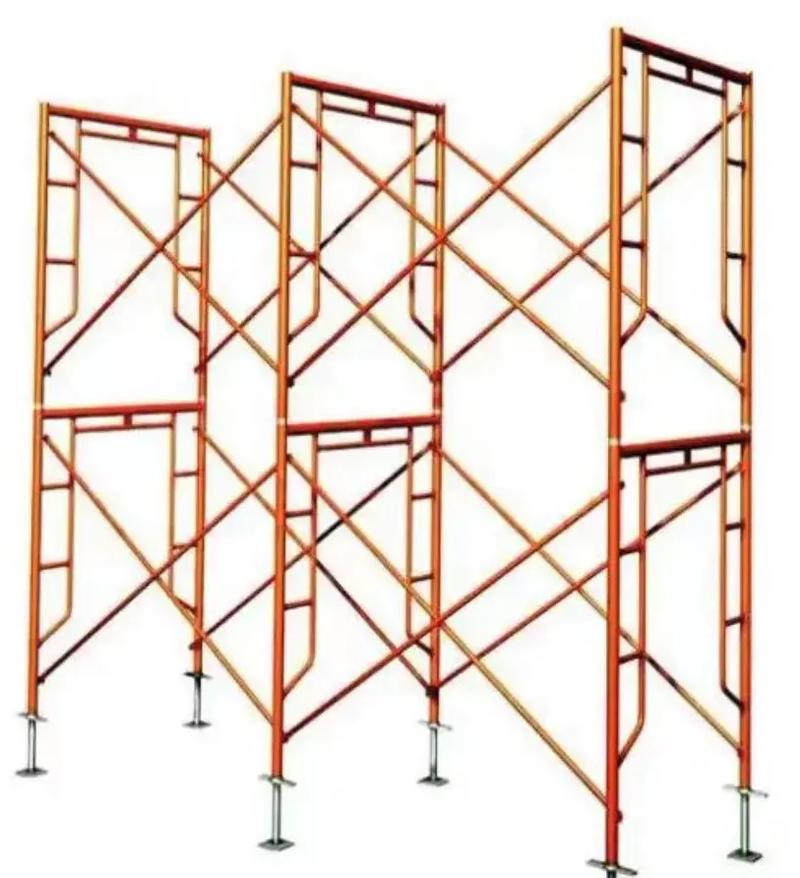

Key Inspection Point 2: Conduct a comprehensive inspection of the appearance of structural components to eliminate obvious safety hazards. The key points of the inspection are the appearance of the core components of the scaffolding: For the poles, check for bending, deformation, and cracks in the steel pipes, uprights, and horizontal bars, and whether the surface corrosion exceeds the standard (rust depth must not exceed 10% of the pole wall thickness). If there is large-area corrosion or obvious cracks, it is directly deemed unqualified. For welds, carefully inspect the welds at the pole connections. If the welds are incomplete, cracked, or detached, it indicates insufficient structural strength, and such items must not be purchased. For fasteners, check the opening and closing flexibility and wear. If the fasteners are deformed, cannot fit tightly, or the bolts are stripped, it will affect the connection stability and must be resolutely rejected. In addition, check for damage and deformation of the scaffold boards, whether wooden scaffold boards are rotten, and whether steel scaffold boards have holes, ensuring the integrity of the scaffold board bearing surface.

Inspection Point Three: Key Performance Testing to Identify Hidden Damage. After the appearance inspection is passed, simple performance testing is required. The quality of scaffolding members can be assessed by tapping them; a clear, crisp sound indicates good material quality, while a dull sound may indicate internal cracks or rust. Couplers should undergo tensile testing to ensure they do not loosen or fail under rated tension. For bulk purchases, it is recommended to randomly select 3%-5% of components for load-bearing capacity testing by a professional testing institution to ensure they meet safety requirements. Simultaneously, check the completeness of scaffolding accessories, such as bases, top supports, and safety net hooks, to avoid assembly and use issues due to missing parts.

Key Checkpoint Four: Transaction details and after-sales agreements to reduce future risks. Prioritize reputable secondhand building materials markets or suppliers to avoid private transactions. Sign a written purchase contract clearly specifying the scaffolding specifications, quantity, quality standards, warranty period, and accountability for quality issues to avoid future disputes. For bulk purchases, consider a “trial before payment” agreement to test the stability and safety of the scaffolding in actual construction scenarios. Also, request the seller to provide transportation services to avoid secondary damage caused by improper loading and unloading during transport. In short, the core principle of purchasing used scaffolding is “risk avoidance first, then rigorous inspection.” This involves proactively mitigating core risks such as structural safety and compliance, and conducting thorough inspections across four dimensions: qualification verification, visual inspection, performance testing, and adherence to the agreed-upon terms. If obvious damage, non-compliance, or the inability to provide relevant documentation are found, do not compromise due to low prices. Only by strictly controlling the procurement process can the safe use of used scaffolding be ensured, truly achieving a balance between cost control and construction safety.